- Receiving Hoppers, Scales

- Amendment Storage

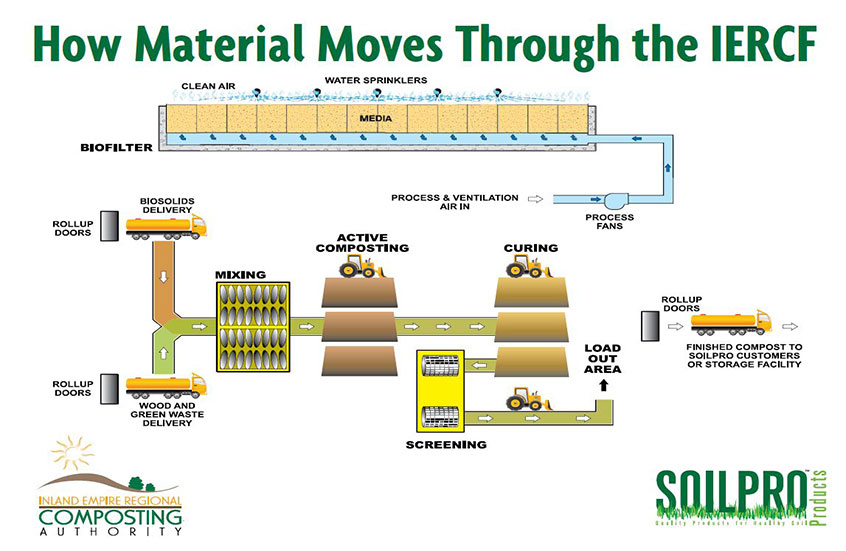

- Pug Mill Mixing

- Pile Building

- Approximately 21 Days of “Active” composting

- Approximately 21 Days of Curing

- Product Transfer (conveyors and front end loaders)

- Screening

- Product Load Out

COMPOST PROCESS

The entire composting process at the IERCF takes approximately 60 days. In the first few weeks of composting, temperatures are much higher due to the high level of microbial activity within the compost piles. Microbes break down the carbonaceous material transforming it into humus-like compost. The material is then aged (cured) for about a month allowing it to cool down and stabilize before it’s screened for customer use.

Aerated Static Pile (ASP) Composting is an EPA-approved method of composting where air is forced through loosely piled carbonaceous feedstocks such as biosolids and green waste. The IERCF uses the ASP method of composting by drawing air through the compost piles with fans and exhausting the foul air through a biofilter. The biofilter satisfies air regulations and controls odor emissions.

Every year, the IERCF produces approximately 230,000 cubic yards (90,000 tons) of high-quality compost which is marketed under the name SoilPro Products. Parties interested in purchasing compost should contact the Sales Department at (909) 993-1500.

- Fully Enclosed 410,000 Sq. Ft. Building situated on 24 acres

- State-of-the-Art, subsurface aeration system (up to 800,000 cfm)

- Up to 12 Air Changes per Hour in Composting Area

- Biofilter (3 acres) for Odors and Air Emissions (per South Coast AQMD)

- Automation of Fans for pile Aeration based on temperature probes

- Variety of Automated Conveyor Systems

- Biosolids – 150,000 Tons/Year (75,000 each for LACSD and IEUA)

- Bulking Agents & Feedstocks (Manure, Green Waste, Etc.) – 60,000 Tons/Year

- Class A Exceptional Quality Compost

- Sold in bulk to landscapers, farmers, nurseries and top soil blenders